sales@besthardware.in - GST NO. : 27AECPT4419C1ZN

Industrial Bearing Puller

Leading Exporters and Wholesaler of 20 Ton Hydraulic Bearing Puller, 30 Ton Hydraulic Bearing Puller Set, Hydraulic Bearing Puller 20 Ton with Separate Hand Pump and Hydraulic Bearing Puller 50 Ton from Mumbai.

| Business Type | Exporter, Supplier |

| Material | Mild Steel |

| Feature | Durable, High Quality |

| Application | Industrial |

| Working Pressure | 700 BAR |

| Color | Yellow Colour |

| Capacity | 5 TON - 50 TON |

Preferred Buyer From

| Location | Worldwide |

A hydraulic bearing puller is a specialized tool used to remove bearings, gears, pulleys, and other press-fitted components from shafts or housings. Here are the key features and benefits of a hydraulic bearing puller:

Hydraulic Power: Unlike traditional mechanical pullers that rely on manual force or mechanical advantage, hydraulic pullers utilize hydraulic pressure to generate immense pulling force. This makes them capable of handling stubborn or tightly-fitted bearings and components that are difficult to remove with manual methods alone.

Versatility: Hydraulic bearing pullers come in various sizes and configurations to accommodate different sizes and types of bearings and components. They can be used for both internal (inside a bore or housing) and external (on a shaft) pulling applications.

Efficiency: The hydraulic mechanism allows for precise control over the pulling force, making the removal process more efficient and reducing the risk of damage to the bearing or surrounding components.

Safety: Hydraulic pullers are designed with safety in mind. The controlled application of force minimizes the risk of sudden releases or accidents during the pulling operation. Some models may also feature safety features such as pressure relief valves to prevent overloading.

Ease of Use: Operating a hydraulic bearing puller is generally straightforward. Most models come with a hydraulic pump or cylinder that applies pressure to the pulling mechanism (such as jaws or hooks), allowing the user to gradually and evenly extract the bearing or component.

Time-saving: Compared to traditional methods that may involve heating, hammering, or using manual pullers, hydraulic pullers can significantly reduce the time and effort required to remove stubborn bearings or components. This efficiency is particularly valuable in industrial settings where downtime needs to be minimized.

Durability: Hydraulic bearing pullers are typically constructed from robust materials such as hardened steel for the pulling arms and high-strength alloys for the hydraulic components. This ensures durability and longevity, even under heavy use in demanding environments.

Maintenance: Regular maintenance, such as lubrication of hydraulic components and inspection of wear parts, helps ensure reliable performance and extends the service life of the hydraulic bearing puller.

Overall, a hydraulic bearing puller is an essential tool in maintenance workshops, manufacturing facilities, and automotive repair shops where the efficient and safe removal of bearings and other press-fitted components is required. Its ability to deliver controlled, high-force pulling makes it indispensable for tasks that demand precision and reliability.

| Business Type | Exporter, Supplier |

| Type | Hydraulic Bearing Puller Set,Hydraulic Bearing Puller |

| Model | BESTUL-20T |

| Application | Industrial |

| Condition | NEW |

| Capacity | 20 Ton |

Preferred Buyer From

| Location | Worldwide |

A hydraulic bearing puller is a tool used to remove bearings from shafts or housings with the help of hydraulic pressure. It consists of a hydraulic cylinder that generates force, a pulling attachment that grips the bearing, and various accessories to adapt to different bearing sizes and types.

Here's how it typically works:

Setup: The hydraulic bearing puller is positioned over the bearing to be removed, with the pulling attachment securely placed around the bearing.

Hydraulic Pressure: Hydraulic pressure is applied using a hand pump or another hydraulic device. This pressure is transmitted to the pulling attachment, exerting force on the bearing.

Extraction: As hydraulic pressure builds up, it creates a force that gradually pulls the bearing off the shaft or out of the housing. This process may require some time depending on the size and tightness of the bearing.

Removal: Once the bearing is sufficiently loosened, it can be removed manually or with the help of additional tools. The hydraulic pressure is then released, and the bearing puller is disassembled.

Hydraulic bearing pullers are particularly useful for removing bearings in situations where traditional methods, such as manual pulling or using a mechanical puller, may not be effective due to tight clearances or high friction. They're commonly used in automotive repair, industrial maintenance, and machinery servicing. Versatility: Hydraulic bearing pullers are versatile tools that can be used to remove various types of bearings, including ball bearings, roller bearings, sleeve bearings, and others. They come with interchangeable pulling attachments and accessories to accommodate different bearing sizes and configurations.

Safety: Hydraulic bearing pullers are designed with safety in mind. The use of hydraulic pressure reduces the need for excessive physical force, minimizing the risk of strain or injury to the operator. Additionally, many models feature built-in safety features such as overload protection and pressure-relief valves to prevent damage to the tool or the bearing being removed.

Efficiency: Compared to traditional manual methods, hydraulic bearing pullers offer increased efficiency and speed in bearing removal. The hydraulic force applied is evenly distributed, allowing for controlled and precise extraction without causing damage to the bearing or surrounding components.

Accessibility: Hydraulic bearing pullers are designed to access bearings in tight or confined spaces where manual or mechanical pullers may not fit or be effective. Their compact size and flexible design make them ideal for use in challenging work environments, such as engine compartments or machinery assemblies.

Maintenance: Proper maintenance of hydraulic bearing pullers is essential to ensure their continued performance and longevity. This includes regular inspection of hydraulic components for leaks or damage, lubrication of moving parts, and replacement of worn or damaged accessories as needed. Overall, hydraulic bearing pullers are indispensable tools for mechanics, technicians, and maintenance professionals involved in bearing replacement and repair tasks across various industries. Their ease of use, versatility, and efficiency make them a valuable asset in any workshop or maintenance facility.

| Business Type | Exporter, Supplier |

| Application | Industrial |

| Material | Mild Steel |

| Brand Name | BESTLIFT |

| Color | YELLOW |

| Working Pressure | 700 BAR |

| Capacity | 5 TON - 50 TON |

Preferred Buyer From

| Location | Worldwide |

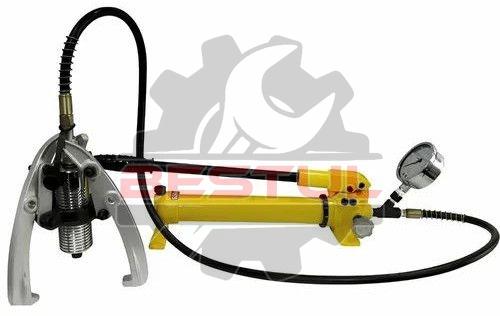

A hydraulic puller with a separate hand pump is a tool used for removing components that are press-fitted or tightly secured, such as gears, bearings, or pulleys. The design typically involves two main parts:

-

Hydraulic Puller: This part consists of the pulling mechanism itself, which is attached to the component you want to remove. It usually has arms or jaws that grip the component and apply force to pull it off.

-

Separate Hand Pump: This is a manual pump used to generate hydraulic pressure. It's connected to the puller via hydraulic hoses. By operating the hand pump, you create hydraulic pressure that is transmitted to the puller, which then exerts the force needed to separate the component from its housing.

Benefits of a Hydraulic Puller with Separate Hand Pump

-

Increased Force: Hydraulic pullers can generate much more force than manual or mechanical pullers, making them suitable for larger or more stubborn components.

-

Precision: The separate hand pump allows for controlled application of force, reducing the risk of damaging the component or surrounding parts.

-

Versatility: The separate pump can be used with various pullers, and you can often switch between different puller heads or attachments depending on the job.

-

Ease of Use: Using a hand pump requires less physical effort compared to mechanical pullers or other manual methods.

Common Uses

- Automotive Repairs: Removing gears, pulleys, or bearings from shafts.

- Industrial Maintenance: Extracting components from machinery or equipment.

- Construction: Removing parts from heavy machinery.

Safety Tips

- Ensure Compatibility: Make sure the puller and hand pump are compatible and rated for the force you need.

- Check for Wear: Regularly inspect hoses and connections for leaks or damage.

- Use Proper Techniques: Follow the manufacturer’s instructions for setup and operation to avoid accidents.

If you have any specific questions about using or maintaining this tool, feel free to ask!

| Business Type | Exporter, Supplier |

| Application | Industrial |

| Capacity | 5 TON - 50 TON |

| Material | Mild Steel |

| Brand | CK |

| Color | Yellow |

| Max. Reach | 300MM |

| Reach | 140MM TO 300MM |

| Spread Range | 200MM TO 500MM |

Preferred Buyer From

| Location | Worldwide |

A hydraulic gear puller is a specialized tool used for removing gears, bearings, pulleys, and other components from shafts or axles. It employs hydraulic pressure to exert a strong, even force, making it easier to dislodge parts that are stuck or tightly fitted.

Key components of a hydraulic gear puller typically include:

Hydraulic Ram: This is the main component that generates hydraulic pressure. It applies force to the pulling arm or jaws.

Pulling Arm or Jaws: These are the parts that actually grip the gear or component to be pulled. They can be adjustable to accommodate different sizes of gears or bearings.

Pump Mechanism: Usually a manual pump that allows you to control the hydraulic pressure applied to the ram. Some advanced models may have electric pumps for easier operation.

Pressure Gauge: Some hydraulic pullers have a pressure gauge to help you monitor the amount of force being applied.

Safety Features: Hydraulic pullers often come with safety features such as overload protection or pressure release valves to prevent damage to the tool or the components being pulled.

Using a hydraulic gear puller involves positioning the arms or jaws around the gear or bearing, applying hydraulic pressure using the pump mechanism, and gradually pulling the component off the shaft or axle. This method is preferred for its efficiency and reduced risk of damage compared to traditional mechanical pullers or manual methods.

High Force Application: Hydraulic gear pullers can exert significant force, often much higher than what can be achieved with manual or mechanical methods. This is particularly useful for stubborn or tightly fitted components.

Even Force Distribution: Hydraulic systems provide a smooth and even distribution of force, which helps in reducing the risk of damage to both the gear being pulled and the shaft or axle it's mounted on.

Versatility: Hydraulic pullers are versatile tools that can be used for a variety of applications beyond gears, such as bearings, pulleys, sprockets, and other press-fitted parts.

Efficiency: They are generally quicker and more efficient than manual methods since they require less physical effort and can apply continuous pressure without the need for constant adjustments.

Safety: Many hydraulic pullers come with safety features like pressure relief valves or overload protection mechanisms, which enhance safety during operation.

Components and Operation:

Adjustable Arms or Jaws: The pulling arms or jaws are typically adjustable to accommodate different sizes and types of components. This adaptability makes them suitable for various pulling tasks.

Manual or Electric Pump: Depending on the model, hydraulic pullers can come with manual hand pumps for smaller units or electric pumps for larger ones, offering convenience and ease of use.

Pressure Gauge: Some hydraulic pullers feature a pressure gauge that allows you to monitor the amount of force being applied, ensuring precise control during operation.

Durability: Hydraulic pullers are built to withstand the high pressures and forces they generate, making them durable tools that can handle demanding tasks over extended periods.

Applications:

Industrial and Automotive Use: Hydraulic gear pullers are commonly used in industrial settings, such as manufacturing, maintenance, and repair operations. They are also widely employed in automotive repair shops for tasks like removing bearings, gears, and other components from shafts and axles.

Field Service: Their portability and ease of use make hydraulic pullers suitable for field service applications where tools need to be transported to different locations for repairs or maintenance.

Overall, hydraulic gear pullers are essential tools for professionals who deal with machinery, equipment, and vehicles, offering efficiency